Stainless steel coil slitting is the process of cutting wide master coils into narrower width coils with cutting knives. The slit coils produced make their way into a variety of industries and products such as, automotive trim, electronics, medical devices, HVAC ducts, household appliances, springs, and more.

This article provides a look at what slitting stainless steel is, how it’s used, and the various alloys you can cut with this method.

What is Stainless Steel Coil Slitting?

Stainless steel starts as large slabs of metal, which are rolled to thinner gauges and recoiled into a large roll. These large, wide coils are called Master Coils. Master coils are then cut down to narrower widths to customer specifications that best suit their manufacturing and process needs.

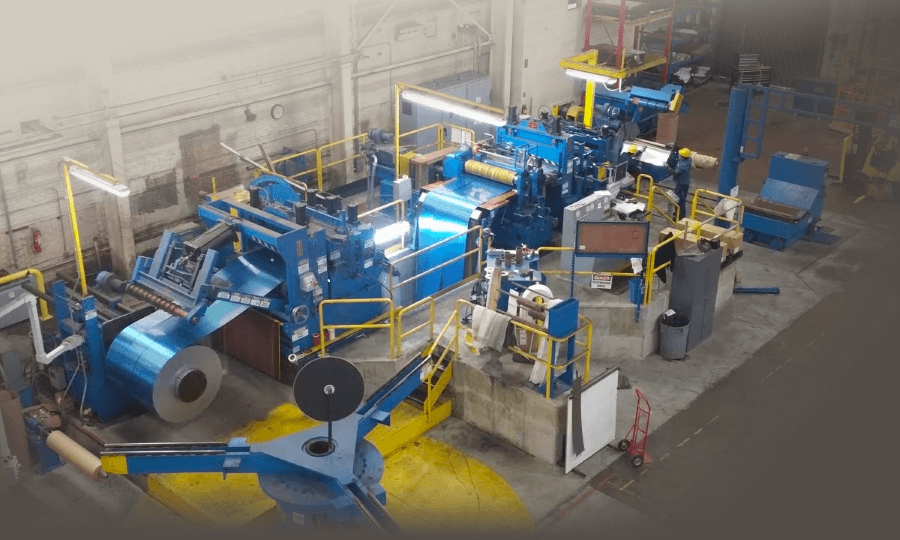

Stainless steel coil slitting processes has three steps: Uncoiling to flatten the metal out, blades (called knives) for cutting, and a recoiler for winding the metal back into a coil. The three processes need proper alignment to ensure the strips are cut to proper tolerances.

The equipment can use different circular blades to accommodate different gauges and types of stainless steel for slitting. It uses one upper and one lower knife, which can be moved to get different widths for the new strips. The goal with coil slitting is to keep the length of the original coil while reducing the width to that needed for a particular application.

Combined Metals can slit your stainless to widths from .187” up to 51 inches. The cut pieces are sometimes called strip coils, slit coils, rolls, rolled strip, slit strip, strands, or strips.

The pieces need to be accurately slit with uniform edges with minimum burr, which calls for maintaining sharp knives. Dull blades give you burred edges, wave, camber, and other issues that can cause the slit piece to not be useful for a customer’s requirements. Combined is known for it’s superior #3 slit edge.

Applications for Stainless Coil

Once your master coil has been cut down into narrower widths, it can be used in many industries and a lot of different ways. The chief difference in application is based on the grade or type of steel used.

Some of the more common uses for stainless steel coil are to make surgical instruments, springs, heat, exchangers, and cutlery. The automotive industry is one of the fast-growing users, especially for decorative parts and the exhaust system. You’ll also find polished coil used extensively in construction for everything from handrails to decorative touches.

Additional Industries that use Stainless Steel Slit Coil:

- Aerospace

- Automotive

- Construction

- Consumer Products

- Electronics

- Medical

- Truck and Trailer panels/doors

- Oil and Gas Industry

Available Alloys

Steel is broken down into various grades by the Society of Automotive Engineers, which sets the standards. The stainless steel grade is then broken down into various types based on the alloy.

The corrosion-resistant properties of stainless steel commonly comes from the addition of chromium, but many alloy combinations make up today’s stainless steel. More resistance can be gained by increasing the levels of chromium or adding nickel or molybdenum.

Stainless steel is broken down into families that give you an immediate idea of what is in the alloy and the ratios. The four distinct families are:

- Austenitic Stainless Steel – Chromium (16-26%), nickel (6-12%), and iron (300 series alloys are austenitic)

- Ferritic Stainless Steel – Chromium (typically 12.5% or 17%) and iron non-hardenable by heat treatment: (430, 434, 439, 444 are common ferritic alloys)

- Duplex Stainless Steel – Chromium (18-26%) nickel (4-7%), molybdenum (0-4%), copper and iron (2205, 2304 are common duplex alloys)

- Martensitic Stainless Steel – Carbon (0.2-1.0%), chromium (10.5-18%) and iron (410 and 420 are common martensitic alloys)

There are more than 150 types of stainless steel listed by the SAE, each with a three-digit code that tells you about the specific composition of the alloy.

For example, the 200 series is an austenitic chromium-nickel-manganese alloy that serves as a general-purpose steel. The more commonly used types can be found in the 300 and 400 series stainless steel alloys.

Type 304 stainless steel is the most commonly used austenitic grade, seen as the classic stainless steel and used extensively by automotive, chemical, food, oil/gas, and medical industries. Type 316 is the second most common, usually chosen over 304 for better corrosion resistance and more strength at higher temperatures thanks to the addition of molybdenum.

The addition of the letter “L” to the series number designates an alloy with a lower amount of carbon. For example, Type 316L stainless steel is an extra-low carbon grade often used in watches, heat exchangers, and restaurant kitchens. The lower carbon makes it a better choice if welding is needed.

400 series includes both ferritic and martensitic alloys. Ferritic is known for better corrosion resistance while martensitic has more toughness. Martensitic can be heat treated and ferritic cannot.

Buying Stainless Steel Steel Slit Coil?

Advances in stainless steel coil slitting equipment make it possible to produce precise cuts to give you stainless steel slit coil that perfectly meets your requirements. The wide range of steel alloys available for slitting means you can find the right set of characteristics to fit with your project. If you’re interested in learning more about our stainless-steel slitting capabilities or purchasing, contact us to talk to our sales team.